If your home was built before the 1970s, your plumbing system might be outdated and prone to issues. Older materials like galvanized steel, cast iron, lead, and polybutylene are common in these homes, each with unique problems. Here’s what you need to know:

- Galvanized Steel & Cast Iron: Rust buildup restricts water flow and weakens pipes, leading to leaks and potential structural damage.

- Lead Pipes: A major health risk as lead can leach into drinking water. Homes built before 1986 may still have lead pipes or solder.

- Polybutylene Pipes: Prone to cracking due to chemical reactions with water disinfectants, often failing within 10–15 years.

Replacing these materials is often necessary to avoid costly damage and ensure safety. Modern options like PEX and copper offer durability and efficiency, while advanced diagnostic tools help pinpoint issues with minimal disruption. Acting early can save money and prevent emergencies.

CAST IRON REPLACEMENT IN 100 YEAR OLD BUILDING

Common Pipe Materials in Older Homes and Their Problems

Common Pipe Materials in Older Homes: Problems, Lifespan, and Replacement Costs

When you take a closer look at the pipes hidden within older homes, you might uncover potential risks that aren’t immediately obvious. The type of material your pipes are made from plays a big role in determining what kinds of issues you might face and how urgently they need attention. Below, we’ll break down the most common pipe materials found in older homes and the challenges they bring.

Galvanized Steel and Iron Pipes: Corrosion and Deterioration

Galvanized steel pipes were a go-to choice in homes built before the 1960s. These pipes were coated with zinc to prevent rust, but over time, that protective layer wears off. Once the zinc is gone, the pipes start corroding from the inside – a process known as internal pipe corrosion. As rust builds up, it clogs the pipes, reduces water flow, and encourages the formation of mineral deposits. This can lead to brown or reddish water and noticeable drops in water pressure.

Most galvanized pipes installed before 1960 are now at the end of their lifespan, making corrosion a pressing concern. There’s another risk too: if these pipes were once connected to lead service lines, rust inside the pipes can trap lead particles and release them into your water supply.

"Rust-corrosion accumulates inside the pipe and causes a plumbing version of arteriosclerosis, with the gradual hardening-of-the-arteries narrowing the diameter of the pipe." – McGarry and Madsen

Other materials, like lead and polybutylene, come with their own unique hazards.

Lead Pipes: Health Hazards

Lead pipes were widely used between the late 1800s and early 1900s because they were durable and could last over a century. But despite their longevity, the health risks they pose are too severe to ignore. Lead pipes were banned for new installations in the U.S. in 1986, yet millions of older homes still rely on them. For instance, Chicago alone has around 400,000 lead service lines still in use.

The problem with lead is that it can leach into drinking water through corrosion, and it’s undetectable – you can’t taste, smell, or see it. The EPA has made it clear: there’s no safe level of lead exposure, particularly for children. Because of these dangers, new regulations now require nearly all lead water pipes to be replaced by 2037.

If you suspect your home has lead pipes, there’s a simple test: gently scratch the surface of the pipe with a coin. If it’s lead, the metal will feel soft and reveal a shiny silver color. You might also notice a bulb-like or snake-like shape near the shutoff valve. Given the serious health risks, replacing lead pipes is not just recommended – it’s necessary.

Polybutylene Pipes: Cracking and Failure

Polybutylene (PB) pipes were a popular choice between the late 1970s and mid-1990s because they were inexpensive and easy to install. However, they’ve since gained a reputation for sudden and catastrophic failure. These gray plastic pipes react with chlorine and other disinfectants in municipal water, which causes them to become brittle and crack from the inside out. Many polybutylene pipes fail within just 10 to 15 years, leading to costly water damage.

Polybutylene pipes are usually gray but can also be blue (for cold water) or black (for outdoor use). They’re often marked with the code "PB2110."

"Because these pipes [polybutylene] often run through finished spaces, a small failure can escalate to a large insurance claim very quickly." – Delta Plumbers

If you spot gray plastic pipes under your sinks or where pipes enter walls, it’s time to call a professional. Some insurance companies may even refuse to cover water damage caused by polybutylene pipe failures, so it’s worth checking your policy.

Main Challenges When Replacing Pipes in Older Homes

Replacing old plumbing systems comes with its own set of challenges. Let’s dive into some common hurdles and practical solutions.

Accessing Pipes Behind Walls and Floors

One of the biggest obstacles in repiping older homes is reaching the pipes themselves. Plumbing in these homes is often tucked behind drywall, under floors, or in tight crawl spaces. To access them, walls and floors need to be opened up, creating dust, debris, and potential structural concerns.

As Moen highlights:

"Repiping a house involves demolition, plumbing, reconstruction, and in some cases, using an open flame."

Without blueprints, identifying pipe routes becomes even trickier. Over time, a home’s foundation may settle, leading to "pipe bellies", where sagging pipes create negative slopes that hinder water flow.

A smart approach is to align pipe replacement with larger renovations, like a kitchen or bathroom remodel, to cut down on labor and restoration costs. Using flexible materials like PEX, which can navigate existing wall cavities, also reduces the need for extensive demolition. Advanced tools like drain cameras can help plumbers locate pipes with precision, minimizing unnecessary damage to walls and floors.

But the challenges don’t stop at access – internal pipe damage caused by hard water is another major issue.

Hard Water Damage and Mineral Deposits

Hard water, rich in minerals, can wreak havoc on pipes over time. Mineral deposits build up inside the pipes, narrowing their diameter, reducing water flow, and increasing pressure, which may eventually lead to leaks or bursts.

Atlantis Plumbing explains:

"All pipes will eventually suffer from scale (where a buildup of debris and mineral deposits are created inside the pipe). This reduces the internal diameter of the pipe, reducing the amount of water that can go through the pipe."

Older materials like galvanized steel and cast iron are especially prone to rust and scale buildup. This not only disrupts water flow but can also cause chunks of debris to break off, leading to clogs or damage to newer fixtures. Homeowners might hear unusual noises – like banging, rattling, or whistling – caused by water struggling to pass through these narrowed pipes.

To combat these issues, consider replacing old pipes with materials like PEX or PVC, which resist mineral buildup. Adding a water softener can further protect the new system by reducing the likelihood of future scale deposits. It’s also a good idea to upgrade faucets and showerheads during the process to avoid clogging modern fixtures with leftover sediment.

Weighing Repair Costs Against Replacement

Deciding whether to patch a leak or replace the entire plumbing system can be a tough call. While repairs may seem cheaper upfront, frequent issues often signal that the system as a whole is deteriorating. In these cases, full repiping is a smarter long-term investment that can also increase property value.

The cost of whole-house repiping typically ranges between $3,000 and $16,000, with more complex projects sometimes exceeding $20,000. However, a major pipe failure could lead to even higher costs due to secondary damage, such as mold remediation, drywall repair, and flooring replacement. Upgrading your plumbing can also enhance resale value and provide peace of mind for years to come.

The lifespan of pipes depends on the material used. For example, galvanized steel usually lasts 30–40 years, while copper pipes can last 50–100 years. If your galvanized pipes are nearing the 35-year mark and showing signs of wear, replacing them now could save you from more expensive repairs down the line.

Keep an eye out for corrosion signs, such as pitting, flaking, dimpling, or a bluish tint on exposed pipes. A sudden spike in your water bill might also indicate hidden leaks and the need for a full system replacement.

| Pipe Material | Average Lifespan (Years) | Estimated Cost per Linear Foot |

|---|---|---|

| Galvanized Steel | 30–40 | N/A (Obsolete) |

| Copper | 50–100 | $2–$12 |

| PEX | 50–80 | $0.40–$4 |

| CPVC | 50–75 | $0.50–$3 |

| PVC | 100 | $0.40–$4 |

sbb-itb-5fe396b

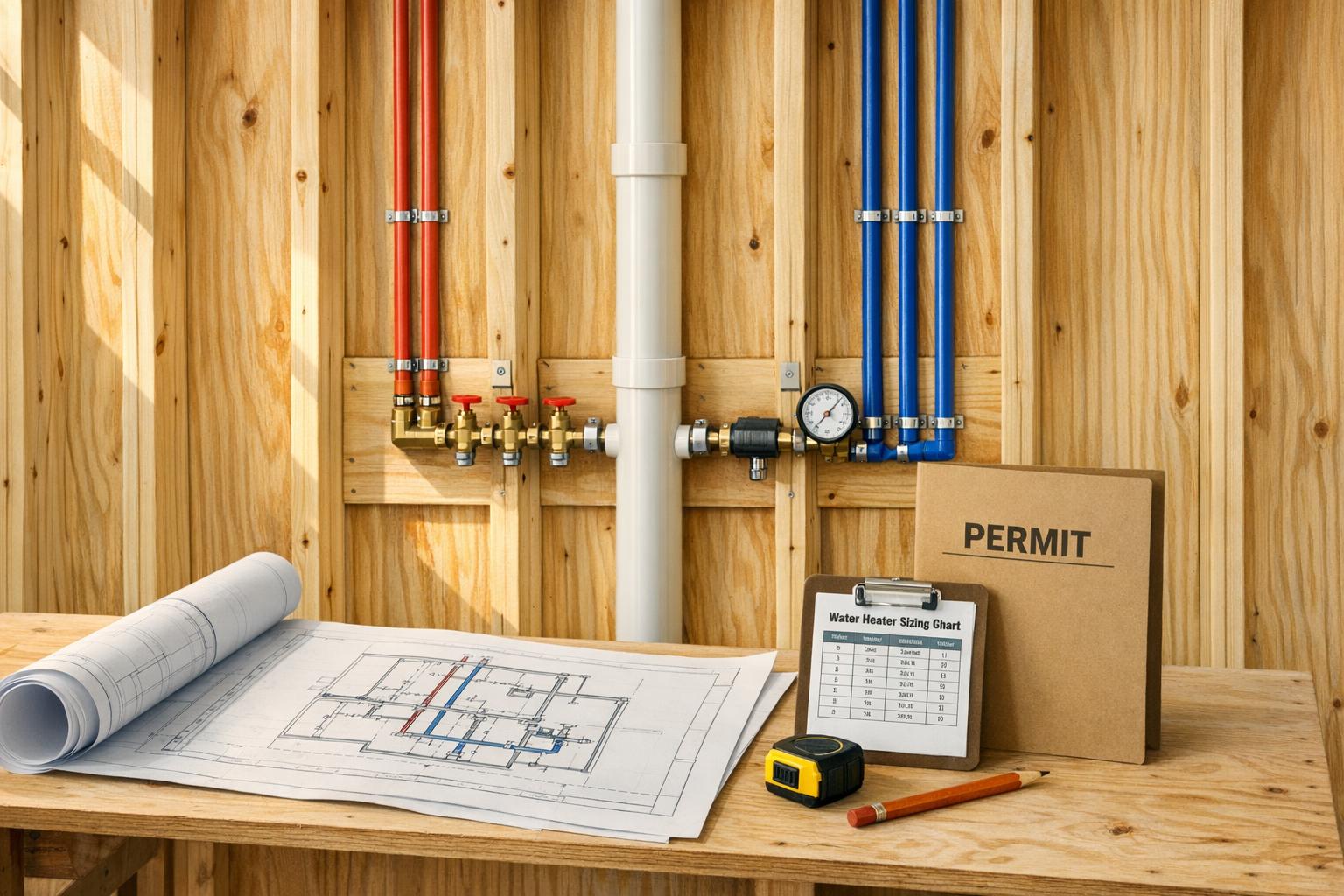

Modern Pipe Replacement Methods and Materials

Dealing with corrosion, access challenges, and hard water issues in older plumbing systems calls for modern solutions. Once you’ve decided to upgrade your pipes, selecting the right materials and techniques is crucial. Today’s methods are built to last longer, install more efficiently, and minimize disruptions compared to older approaches.

Copper and PEX Pipes: Modern Replacement Options

Copper pipes are a long-standing favorite, with a lifespan of 75–100 years. They naturally resist bacteria and corrosion, making them a durable choice. However, they come with drawbacks: high costs, vulnerability to freezing damage, and the risk of pinhole leaks in acidic water. Installing copper also requires soldering with an open flame, which can pose safety concerns in older homes.

PEX (cross-linked polyethylene), on the other hand, has revolutionized residential plumbing. As Family Handyman notes:

"PEX piping is the biggest revolution since the flush toilet".

PEX is far more affordable than copper, costing about $0.30–$0.50 per foot compared to copper’s $1–$3 per foot. Its flexibility allows it to be threaded through existing walls with minimal demolition, and it requires fewer fittings, reducing potential leak points. Additionally, PEX can expand and contract, making it less likely to burst in freezing conditions. However, it does have limitations: it must be kept indoors due to UV sensitivity, and it can be damaged by rodents.

While upgrading materials is a significant step, newer repair methods also aim to minimize the disruption of plumbing projects.

Pipe Relining: A Less Invasive Solution

For sewer or drain pipes, where digging could damage landscaping or hardscaping, pipe relining offers an efficient alternative. This process involves inserting a resin-coated liner into the existing pipe, which is then cured using heat, steam, or UV light to create a durable “pipe within a pipe” [34,35]. As Roto-Rooter explains:

"Roto-Rooter’s Zero-Dig Pipe Restoration Services can bring most old sewers and drainpipes back to life without digging trenches to repair or replace them."

The process begins with cleaning and descaling the pipe. The liner is then inserted using either air pressure (inversion method) or mechanical pulling. Pipe relining is ideal for non-pressurized systems like sewers and drains. However, for pressurized systems, such as water supply lines suffering from corrosion or leaks, full repiping with copper or PEX is usually the better option. As Repipe Specialists point out:

"Pipe relining is a targeted and sometimes less disruptive alternative to repiping, making it a strong choice for pipes that may cause significant disruptions if they are repiped, such as sewer lines and drainage systems".

Diagnostic Tools for Precise Problem Identification

Modern plumbing projects often start with advanced diagnostic tools to locate issues and limit unnecessary demolition. Drain cameras, for example, allow plumbers to inspect the interior of pipes, identifying problems like tree root intrusion, cracks, or blockages. This information helps determine whether a minor repair, partial replacement, or complete repipe is needed.

Electronic leak detection tools are another game-changer, pinpointing the exact location of pipes behind walls or floors. This precision allows plumbers to access problem areas with minimal damage, avoiding large-scale drywall removal. Devices like the Flo Smart Water Monitor and Shutoff can even track pressure loss and flow patterns in real time to detect leaks or other concerns. Companies like Round Rock Plumbing use these technologies – drain cameras and electronic leak detection – to provide accurate assessments before starting any replacement work. These evaluations can also identify hazardous materials, such as lead or polybutylene pipes, that require immediate attention. With these insights, plumbers can recommend the best course of action, whether it’s a full replacement or a targeted repair.

Conclusion

The issues tied to aging pipes demand prompt attention. Old plumbing systems often face problems like corrosion, hidden leaks, and health hazards. Ignoring these issues can lead to extensive damage, including ruined drywall, flooring, and furniture – problems that only get worse over time. Plus, emergency repairs can cost 1.5 to 3 times more than standard rates. For homes older than 40 years, many insurance providers even require repiping before they’ll renew a policy.

Thankfully, modern solutions can tackle these challenges effectively. Materials like copper and PEX, combined with advanced diagnostic tools, allow for precise and durable fixes. Instead of relying on temporary patches, professional inspections can identify the root causes, whether it’s corrosion, mineral buildup, or outdated materials. At Round Rock Plumbing, state-of-the-art technology is used to locate problems and recommend the best course of action, whether that’s a complete repipe or a focused repair.

If you’re noticing signs like discolored water, frequent leaks, or visible corrosion, it’s time to schedule an inspection. Addressing these issues early – before a pipe bursts during a freeze or a hidden leak causes significant damage – can save you thousands of dollars. More importantly, it helps ensure your family’s health and safety. Taking a proactive approach not only solves immediate concerns but also protects your home for years to come.

FAQs

What are the warning signs that my older home’s pipes need to be replaced?

If you live in an older home, there are a few warning signs that your pipes might need to be replaced. Keep an eye out for frequent leaks, water that appears discolored or cloudy, or a noticeable drop in water pressure. Other red flags include noisy or rattling pipes, visible signs of rust or corrosion, and persistent slow drains or clogs. Homes with aging materials like lead or polybutylene pipes should also be evaluated, as these materials can pose safety and reliability concerns.

Taking care of these problems sooner rather than later can save you from expensive water damage or unexpected plumbing disasters. A licensed plumber can inspect your system and guide you on the best solutions for your home.

How can I tell if my home has lead or polybutylene pipes?

To identify polybutylene pipes, look for flexible pipes in gray, black, or blue, typically stamped with "PB2110." These pipes were commonly installed in homes built between the 1970s and 1990s. You can usually spot them near water heaters, under sinks, around toilets, or at the main water shut-off valve.

When checking for lead pipes, look for dull, grayish pipes that feel soft and can be scratched with something like a key or coin. Additionally, lead solder or brass fittings might indicate the presence of lead. If you’re uncertain, reach out to your local water utility. They can perform a lead-service-line inspection or test your water for confirmation.

What are the advantages of choosing PEX pipes instead of copper for pipe replacements?

PEX pipes have become a go-to option for replacing traditional copper pipes, and for good reason. Their flexibility makes installation much simpler, especially in tight or awkward spaces, and they don’t require soldering or a torch. That means quicker installations and lower labor costs.

On top of that, PEX is easier on the wallet compared to copper. It also stands up well against corrosion and mineral buildup, which is a big deal in regions with hard water. Thanks to its strength and versatility, PEX is a dependable choice for plumbing in both homes and commercial buildings.